Flue gas condensation

Optimized the efficiency of flue gas condensation

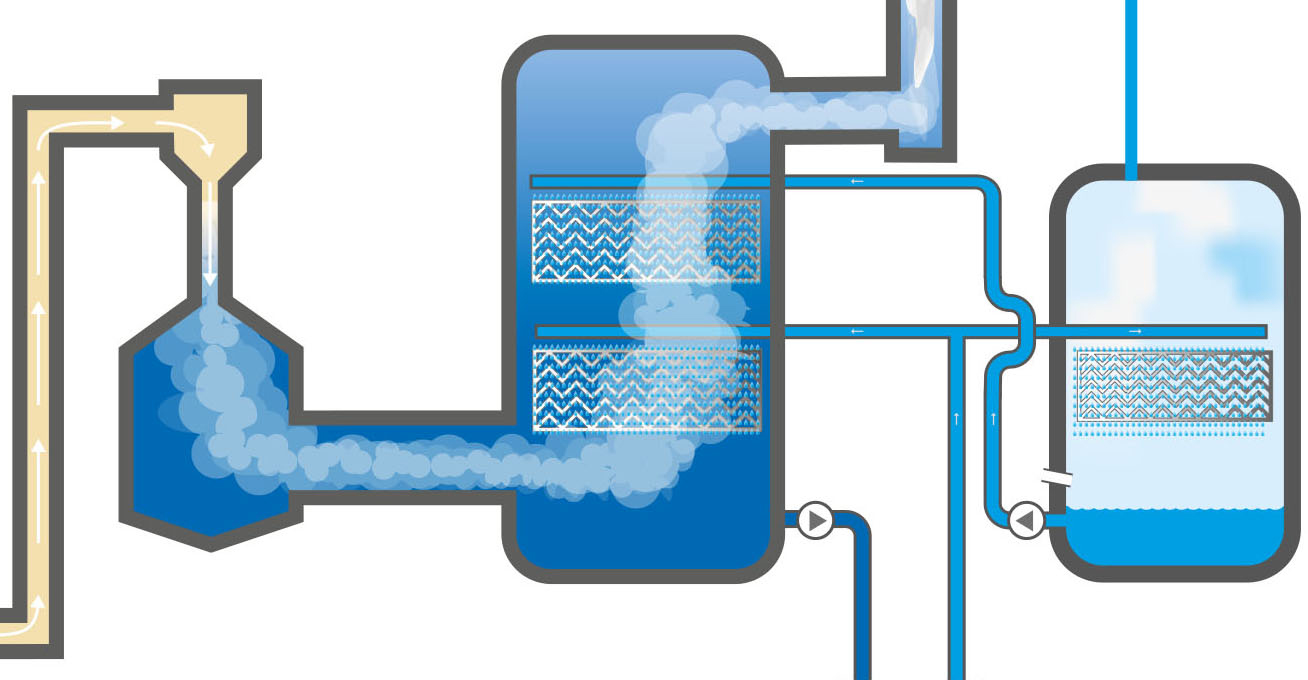

In Scandinavia, heating plants traditionally use flue gas condensation to enhance overall efficiency, raising it by up to 30%.

Dall Energy has further developed and patented the concept which is integrated with the humidification of primary combustion air. This results in increased efficiency and effective removal of particles from the condensate.

Particle removal in condensator

During flue gas condensation the particles from the smoke are naturally caught in the condensate. When the condensate has a high content of particles under normal operations, it can cause trouble smudged heat exchangers, plugged up nozzles and other components generally face a reduced lifetime.

Additionally, the excess condensate must be cleaned before it is discharged into the local sewer system. Dall Energy has developed and patented a system where the particles are removed more effectively than normal. In our system most of the particles are removed by the quench which is situated before the condensator. This process removes particles from the high-concentration source and prevents their reinjection into the flue gas condenser.

Dansk

Dansk Français

Français